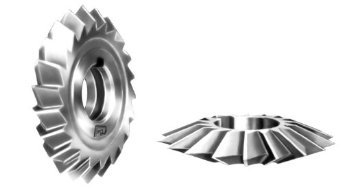

Nc Spot Drill

Price 310 INR/ Piece

MOQ : 5000 Pieces

Nc Spot Drill Specification

- Shape

- Round

- Cutting Capacity

- Up to 10 mm depth

- Material

- High Speed Steel

- Length

- 50 mm

- Usage

- For Cutting and Drilling Purpose

- Cutting Speed

- 50-60 m/min

- Operate Method

- CNC Automated

- Machine Type

- CNC Machine Compatible

- Drill Bits Types

- NC Spot Drill Bit

- Coating

- Uncoated

- Cutting Accuracy

- High Precision

- Operation Type

- Metal Cutting

- Features

- Accurate Spotting, High Wear Resistance

- Hardness

- 62-64 HRC

- Cutting Force

- Low

- Tool Type

- Spot Drill

- Cutter Type

- Single Flute

- Product Type

- Spot Drill

- Diameter

- 4 mm

- Maximum Torque

- Up to 10 Nm

- Color

- Silver

- Processing Type

- Drilling

- Packaging Type

- Plastic Tube

- Surface Treatment

- Polished

- Shank Type

- Straight Shank

- Weight

- 30 grams

- Application

- Automotive, Metalworking, Precision Engineering

- Tip Angle

- 90 Degrees

- Suitable Material

- Mild Steel, Alloy Steel, Cast Iron, Non-ferrous Metals

Nc Spot Drill Trade Information

- Minimum Order Quantity

- 5000 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Nc Spot Drill

Jump on this hot deal for a new NC Spot Drill, engineered for those seeking a rarefied level of precision. This enviable, matchless drilling tool boasts a 4 mm straight shank and a high-speed steel body polished for excellence. Its high hardness (62-64 HRC) ensures lasting performance on materials like mild steel, alloy steel, cast iron, and non-ferrous metals. Designed for CNC automation, it delivers accurate spotting at up to 10 mm depth, with low cutting force and high wear resistance. Perfect for automotive, metalworking, and precision engineering sectors across India.

Exceptional Features & Diverse Applications

The NC Spot Drill is crafted for accurate spotting, high wear resistance, and robust cutting efficiency. With high-speed steel construction and a polished, round, uncoated finish, it excels at high-precision drilling with low cutting force. Its single flute is especially suitable for mild steel, alloy steel, cast iron, and non-ferrous metals. Use it across automotive, metalworking, and precision engineering industries. Compatible with CNC machines, this spot drill is ideal for cutting applications demanding reliability and superior results.

Sample Availability, Export Markets & Policy

Nc Spot Drill samples are available upon proposal amount confirmation, ensuring you experience its market value firsthand. Delivered securely in protective plastic tubes, these samples cater to global requirements. We primarily supply to the main export markets including Asia, Middle East, Africa, and Europe. Our sample policy ensures transparency and reliability, offering prospective partners and distributors a comprehensive insight into product quality before committing to bulk orders.

Exceptional Features & Diverse Applications

The NC Spot Drill is crafted for accurate spotting, high wear resistance, and robust cutting efficiency. With high-speed steel construction and a polished, round, uncoated finish, it excels at high-precision drilling with low cutting force. Its single flute is especially suitable for mild steel, alloy steel, cast iron, and non-ferrous metals. Use it across automotive, metalworking, and precision engineering industries. Compatible with CNC machines, this spot drill is ideal for cutting applications demanding reliability and superior results.

Sample Availability, Export Markets & Policy

Nc Spot Drill samples are available upon proposal amount confirmation, ensuring you experience its market value firsthand. Delivered securely in protective plastic tubes, these samples cater to global requirements. We primarily supply to the main export markets including Asia, Middle East, Africa, and Europe. Our sample policy ensures transparency and reliability, offering prospective partners and distributors a comprehensive insight into product quality before committing to bulk orders.

FAQs of Nc Spot Drill:

Q: How does the NC Spot Drill ensure high precision during operation?

A: The NC Spot Drill is designed with a 90-degree tip angle and robust high-speed steel material, ensuring accurate spotting and minimal deviation, resulting in matchless precision during drilling tasks.Q: What materials is this spot drill suitable for?

A: It is suitable for drilling and cutting applications in mild steel, alloy steel, cast iron, and various non-ferrous metals, making it highly versatile for different industrial needs.Q: When should I use an NC Spot Drill compared to standard drills?

A: Use the NC Spot Drill when high precision spotting is required before final drilling, especially in CNC automated operations where accurate entry points are essential.Q: Where can the NC Spot Drill be applied across industries?

A: It is ideal for use in automotive, metalworking, and precision engineering sectors, especially wherever high accuracy and wear resistance are essential for cutting and drilling.Q: What is the process for ordering sample spot drills?

A: Prospective buyers can request samples by confirming the proposal amount. Samples are then delivered in secure plastic packaging to evaluate the tools market value and suitability for your applications.Q: What is the benefit of the NC Spot Drills high wear resistance?

A: High wear resistance ensures a long operational lifespan, reducing tool change frequency and maintaining cutting accuracy even through extended manufacturing cycles.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in HSS Cutting Tools Category

Hss Square Tool bits

Price Range 300.00 - 2000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : High Speed Steel

Color : Silver

Product Type : Square Tool bit

Equal Angle Cutter

Price Range 500.00 - 5000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Color : Silver

Product Type : Equal Angle

Usage : For Cutting Purpose

Hand Reamer

Minimum Order Quantity : 5 Pieces

Material : High Speed Steel

Color : Silver

Product Type : Hand Reamer

Usage : For Cutting and Drilling Purpose

Center Drill

Minimum Order Quantity : 10 Pieces

Material : High Speed Steel

Color : Silver

Product Type : Drill

Usage : For Cutting and Drilling Purpose

Branch Office:

A2/10, Brij Industries, 109 1st Floor,

GIDC, Makarpura, Badodra - 3900010

Mobile: +918000931330.

Send Inquiry

Send Inquiry